What is MFG Full Form?

MFG full form is “manufacturing”. Manufacturing refers to the process of converting and refining raw materials like wood, ore, and plant items into final products like furniture, metal, and edibles. This is a vital part of the economic system.

Manufacturing is an integral part of the entire economic system. There are a variety of raw materials in our ecosystem like wood, ore, and other food products that require manufacturing to be consumed as a finished product. Manufacturing improves the efficiency of an item and increases its overall value. Therefore, manufacturing is a profitable aspect of the economic chain.

The Process of MFG

The transformation of the raw material into something more efficient gives them additional value. This additional value boosts the overall value of the finished product; thus, manufacturing is a profit-yielding phase of the entire chain. The manufacturing process entails both humans and machinery. However, technological advancements have largely been eliminating manual intervention from the manufacturing process which is one of the reasons for increasing unemployment in the economies.

The manufacturing sector in India has seen varied performance in the past three years. Despite the challenges from COVID-19, there was 8.8% growth in gross value added (GVA) during 2020-21, a substantial recovery of 26.6% in 2021-22, driven by a 35% increase in industrial output, and a continued expansion in 2022-23 with 5.2% growth in industrial production.

The History of Manufacturing

Manufacturing is a procedure that completely transforms the initial raw material in terms of appearance and usage through various steps. Manufacturing has been a part of our society since ancient times. It involved a variety of tools, manual intervention, and chemicals as well.

-

Pre Industrial Era

This refers to the era when manufacturing required manual labour. Goods like textiles, pottery, and tools were handmade. Basic tools and techniques to transform the raw materials were developed in this era.

-

Industrial Revolution (Late18th to19th Century)

However, the industry witnessed advancements from the early 19th century. The industrial revolutions lead to inventions like the Steam Engine. Samuel Hopkins from Philadelphia acquired the first patent in the nation in 1790 for a fertilizer element. Later, British Samuel Slater joined Samuel Hopkins to make the first cotton spinning mill powered by water. The creation of this advanced spinning mill run by manual intervention significantly increased the consistency and output.

-

Mass Production Era (Late 19th to 20th Century)

The first Industrial Revolution happened in the 18th century. And the scale of manufacturing increased dramatically. A majority of the tasks were done by hand before the Industrial Revolution. It was challenging to manage the logistics without computers. Any kind of issue in the supply chain was to be solved by the tradesperson. They identified the requirements and manufactured the needed goods.

The mechanization in the 19th century transformed manufacturing and the craftsmen were turned into wage laborers. Basic tools were replaced by machines and steam engines leading to a change in the industry.

-

Post-World War II

Manufacturing in different economies witnessed revival and expansion after the Second World War. Industries like aerospace, chemicals, and electronics emerged as a result of automation, technological advancements, and the development of materials.

-

Late 20th Century: Computerization

Computer technology and automation developed significantly in the late 20th century. Manufacturing transformed into a more precise and efficient procedure after the introduction of CNC machining and robotics.

The Role of Manufacturing in the Economy

Manufacturing is essential to meet consumer demands and drive economic growth by converting raw materials into usable products. This transformation allows manufacturers to generate revenue and adds value to the economy. Here are the key aspects of the role of manufacturing in the economy.

1. Meeting Consumer Demand and Generating Profit

Manufacturing fulfils consumer demand by supplying in-demand products. The process transforms raw materials into more useful, consumable goods that are saleable. Manufacturers can add value to products by efficiently managing manufacturing costs, and, in turn, increase profits and revenue.

2. Importance of Large-Scale Manufacturing

Mass production, or large-scale manufacturing, enables companies to meet bulk demands while minimizing overall costs. This approach requires high-quality machinery and advanced technology, alongside a skilled workforce to manage sophisticated processes. Innovation and creation are vital in mass manufacturing besides substantial capital investment to sustain and advance the manufacturing process.

3. Economic Impact of High Manufacturing Levels

A robust manufacturing sector signifies high demand for products, spurring economic growth. High manufacturing levels contribute to the establishment of manufacturing units, create employment opportunities, enhance international trade, and promote infrastructural growth. Thus, manufacturing drives overall economic development, creating a foundation for sustainable growth and stability.

Also Read: How Does GST Impact Manufacturers?

Different Types of MFG

There are 5 types of manufacturing as follows:

-

Discrete Manufacturing

A variety of products are manufactured in the discrete method. This dynamic method may vary from a few steps to other steps. Therefore, the final product is also likely to be different from the others.

-

Repetitive Manufacturing

Repetitive manufacturing has been in the industry for a long time and is used most commonly. As the name suggests, repetitive manufacturing produces the same type of product with the same characters one after another. The operation speed may be adjusted by the producer to satisfy the market demand.

-

Job Shop

There is no production line in the job shop and a single product is produced at a time. Job shop rather uses production spaces. These productions are generally done to meet the customer demand. The smaller batch production for customized products increases the cost of manufacturing.

-

Batch Process

A single batch is created by combining multiple batches in this industry. The batch process may include a large number of tiny batches or a single batch with a huge quantity. The batch process may take place over a longer period of time.

-

Continuous Process

The continuous process is similar to the batch process as they both keep running all the time. The process produces identical or similar goods in bulk quantities. However, the raw material used in the continuous process might be different i.e. gas, powder, liquid, slurries, etc.

Manufacturing: The Process

The process of manufacturing is unique for every item and depends on the finished material. However, the basic manufacturing process involves the interference of a man, machine, or equipment to work on some raw material to transform it. The manufactured item looks different and has different characteristics after the steps of conversion, assembling, and final work.

Here is a detailed view of the manufacturing process.

- Plan Creation: The first step before the manufacturing starts is to create a plan. There must be a clear concept for organizing the arrangements. This basic plan will develop on the basis of the consumer type, market demand, nature of goods, and competition level.

- Market Analysis: Market analysis is vital to comprehend the competition, demand type, demand level, prevailing price, and other factors. Analysis also allows for the improvement of production quality to boost sales. Manufacturers may also determine optimal pricing points to attract the highest number of consumers while simultaneously covering manufacturing costs.

- Designing: After a thorough analysis, an appropriate design can be produced to satisfy the requirements of the consumers. It is crucial to consider the design cost as it would impact the profitability after manufacturing. The limitations of the similar products available in the market must also be considered when designing the current product to expand its consumer base.

- Finalizing and Testing: Finalizing and testing are crucial to finally start manufacturing. Acquiring raw materials, arranging resources, allocating funds, and final implementation to create a prototype are included in finalizing. The testing will allow the identification of the flaws, limitations, and defects that need to be fixed right away. The testing must be reliable to limit the negative impacts on the manufacturing.

- Manufacturing: The manufacturing finally begins after assembling all the resources to set up the full-scale process. There must also be arrangements for the storage facility to move the manufactured items from the manufacturing plant to the retail location. The supply chain also has to be reliable and effective.

- Monitoring: The entire manufacturing process must be monitored to ensure its adherence to the criteria and initial plan. It is crucial to evaluate the factors like revenue, cost, profit, and resource allocation. The regulation of design, supply, and utility on the basis of client taste and preferences ensures the achievement of optimal results.

Also Read: 4 Ways Augmented Reality Enhances Manufacturing Efficiency

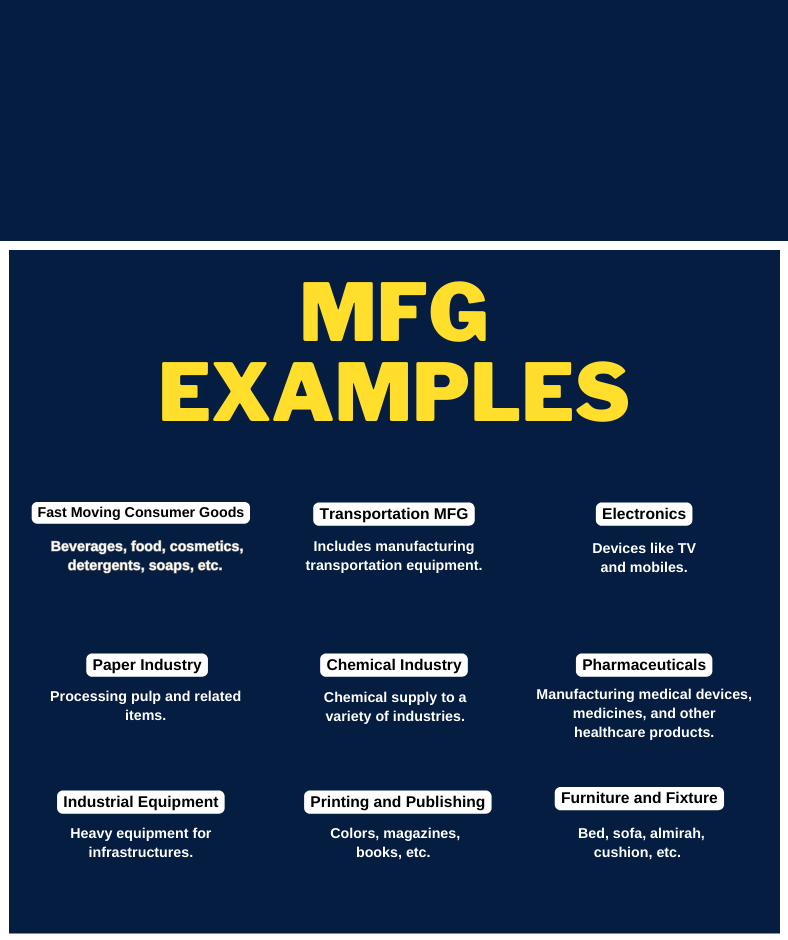

MFG Examples

Let’s understand the MFG with a few examples.

- Fast Moving Consumer Goods- Beverages, food, cosmetics, detergents, soaps, etc.

- Transportation MFG- Includes manufacturing transportation equipment.

- Electronics- Devices like TV and mobiles.

- Paper Industry- Processing pulp and related items.

- Chemical Industry- Chemical supply to a variety of industries.

- Pharmaceuticals- Manufacturing medical devices, medicines, and other healthcare products.

- Industrial Equipment- Heavy equipment for infrastructures.

- Printing and Publishing- Colors, magazines, books, etc.

- Furniture and Fixture- Bed, sofa, almirah, cushion, etc.

The Difference Between Manufacturing and Production

Manufacturing and production are two different concepts, even though both seem quite similar. Here are some key differences between the two.

- Manufacturing converts the raw material into finished products to be consumed by users after the intervention of machines and manual labor. The production does not always rely on raw materials and machines for the final outcome.

- Manufacturing is a more extensive process that requires more investment to acquire the finished good. The production makes the items saleable in the market as an additional process.

| Comparative Factor | Manufacturing | Production |

| Meaning | Merchandise production by utilizing resources to make finished goods. | Combining resources to make something suitable for consumption. |

| Concept | Conversion of raw material into final product | Conversion of input into output |

| Required Resources | Machine and men | Men |

| Input Form | Tangible | Tangible and intangible |

| Output Form | Only goods | Goods and services |

| Final Product | Usable Goods | Utility |

Conclusion

Manufacturing is a vital process that has evolved over centuries and plays a crucial role in the economy. It is a dynamic field that drives economic growth, satisfies consumer demands, and enhances efficiency. Besides merely transforming raw materials into finished goods, manufacturing contributes to employment, technical progress, and global trade as well.

Also Read: 5 Ways to Manage a Manufacturing Business

Frequently Asked Questions

-

What is the meaning of the MFG date?

The MFG date indicates the product’s manufacturing date. It is the date when the item was finally manufactured and converted into something consumable.

-

How does MFG work?

MFG or manufacturing is a process that turns raw materials into goods that are ready to consume.

-

What makes MFG important?

Manufacturing is important as it creates goods to meet the demands of consumers and contributes to the economy by providing jobs.

-

What does MFG mean in business?

MFG in business is the abbreviation for the term “manufacturing”.

-

What is the Manufacturing process?

The process in which raw material is converted, assembled, and changed into a ready-to-use product is known as manufacturing.